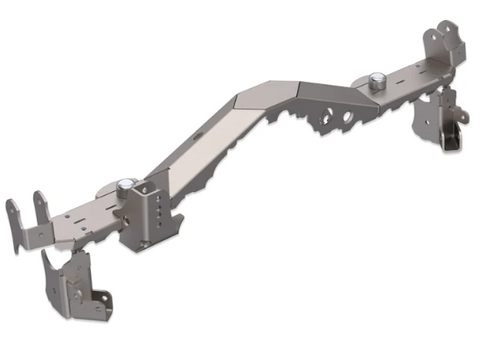

A new era has begun with the arrival of the APEX Truss! Artec Industries is proud to announce the next generation of patent pending axle trusses. This series of trusses not only builds on our experience as the world leader in axle truss design, it brings it to a whole new level of cost savings, strength, weight savings, simplicity of installation, precision fitment, and complete axle protection never before seen in the industry.

The key feature that sets the APEX truss apart is its unique peaked shape top which provides extra rigidity to the whole truss while allowing both a reduction in weight (vs using a thicker material top) and eliminating long weld seams. Previous version with long weld seams which can be lead to extra weld warping of the axle, longer install times and can be inconsistent. Without long seams to weld, now you drop the truss directly on to the axle and weld it to the axle faster.

This heavy duty truss and bracket system is designed to take serious abuse and reinforce your entire axle while also providing the factory link, spring, anti-sway bar and shock locations. The 3/16" thick truss incorporates unique peaked design to strengthen both the axle and incorporate the link brackets for ease of installation and added strength. By using the truss to align the link mounts, hours of work and trial and error can be avoided when compared to the other bracket systems. Simply tack weld the truss on the axle, and all the other brackets fit into place exactly where they need to be.

- Patent pending APEX truss peaked top design provides more rigidity than a flat top truss design

- CNC precision laser cut in-house from 1/4" and 3/16" mild steel

- CNC precision bent in-house for a great fitment

- Designed using 3D models directly from Ford and Jeep

- 70% less welding needed than previous truss designs

- All long seams are bent so you don't need to spend time welding them together

- Dimpled holes provide weight reduction and rigidity and strength

- Contours both the cast steel differential and can be welded with normal MIG welder and moderate pre-heating and post-heating

- OEM location UCAs mount to an ultra high clearance differential bridge

- Multi-piece truss design means smaller packaging and less shipping costs

- Coil brackets and bump stop pads are combined to form an axle tube truss

- Shock brackets have been moved up and out (compared to JK OEM position) for a slightly higher clearance for LCAs

- Low profile design

- Made in the USA

Choose from three different styles of upper control arm brackets:

- Single adjustable truss upper link mount for use with 2.63" wide joints in a 3-link style suspension. DOES NOT include differential top cap

- RockJock Johnny Joints in factory location. Includes differential top cap

- Daystar Bushings in factory location. Includes differential top cap

Important Notes:

- The Front 60 that works with this kit is from Ford SuperDuty F-250 and F-350 trucks from model years 2005+ (coil spring). This truss is not intended for older axles due to different differential offsets

- Trimming of the factory differential casting will be necessary (see instructions). Other fabrication and modifications may be needed due to variances in lift kits and other factors

- Due to the larger casting on the 60 differential, the lower control arm (LCA) brackets are wider than factory location (41.5" center to center). Modifications to your lower control arms will likely be necessary. If you have adjustable arms with flexible style joints (heims, Johnny Joints, etc), modifications may be necessary. UCA brackets are also slightly higher than factory so adjustable arms may be necessary. The shock mounts are also slightly higher (1.25") than stock to clear the LCAs.

- This kit does NOT include any parts for ABS sensors. It is only a bracket kit. Hooking up and configuring these sensors is the responsibility of the end user.

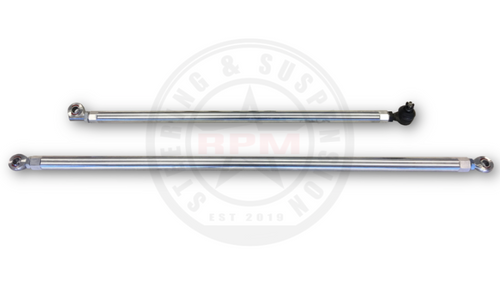

- 60 axles DO NOT MATCH the factory JK 5 lug wheel bolt pattern. New wheels will need to be purchased to do this swap. Brake and steering components are not included in this product but are available separately.

- This kit will likely require bump stop extensions and a new track bar since the steering is different on this axle from the factory axle. The track bar bracket is higher than stock location to allow proper steering geometry.

NOTE: This kit requires general welding and fabrication skills. Welding should only be done by a competent welder who understands different materials. Some welding of cast and mild steel will be used. Artec Industries and Advanced Driveline imply no guarantees or warranties and are not liable for improper installation.

* Some grinding and fitment may be required when installing this kit. Every axle varies slightly and some fabrication may be required. Will require brake line relocation to fit.

** In rare and extreme cases, the truss may come into contact with oil pan. Prior to operating the vehicle, remove the coil springs, cycle the suspension including full compression of both sides simultaneously and add bump stop extensions to prevent damage to oil pan.

Fits:

Jeep Wrangler JK 2 Door (2007-2018)

Jeep Wrangler JK 4 Door Unlimited (2007-2018)

Jeep Wrangler JL 2 Door (2018-Current)

Jeep Wrangler JL 4 Door Unlimited (2018-Current)

Jeep Gladiator JT (2020-Current)